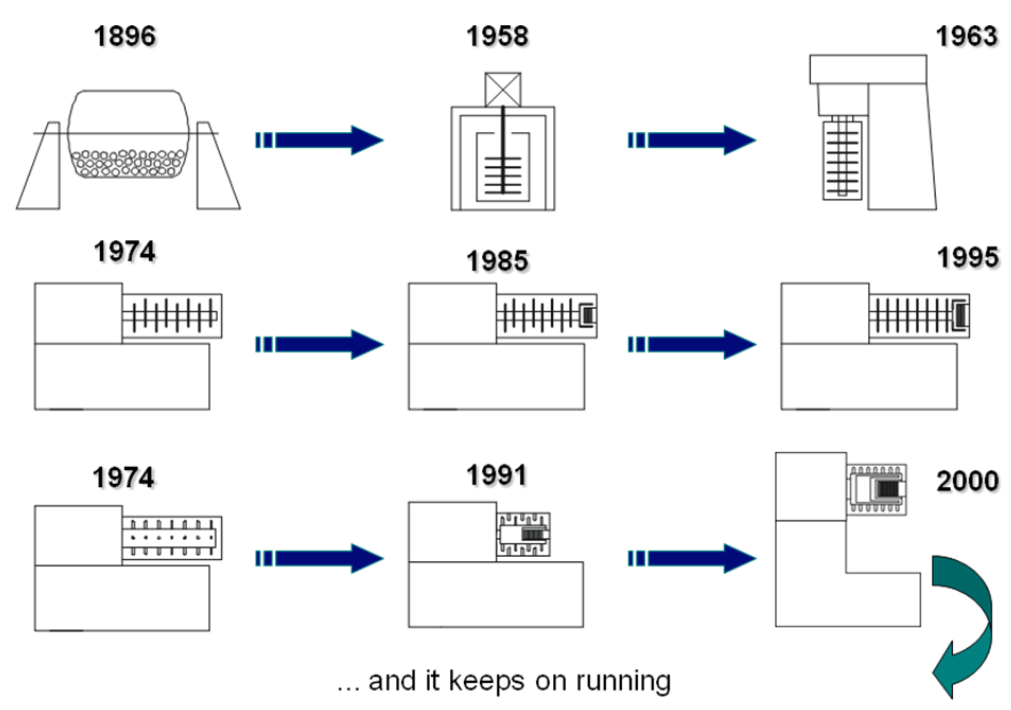

The development of agitator bead mill

Netzsch agitator bead mills are used for many applications in differrent industries like: pint and inks, pigments, pahrmaceuticals and life science products, plant protections, foods, ceramics, paper, electronics and many others.

Influence of Operating Parameters

The grinding process in stirred media mill is influenced by more than 50 operating parameters. These parameters can be divided in parameters of the product suspension, the mixing, wetting or predispersing process before grinding, the grinding media used as well as parameters of the mill itself (Fig. 6)

Parameters of the product suspension are, for instance, the solid content, the viscosity and the particle size distribution of the particles of the fed suspension. Furthermore the structure, the state of agglomeration or aggregation as well as the morphology are improtant parameters of the suspension.

Parameters of the mill are the geometry of the mill, the material of the grinding chamber and the agitator, the size of the mill as well as the parameters like the throughput rate or the stirrer tip speed.

The tools actualy used for comminution, desaggregation or dispersion are the grinding media. The grinding media material, their filling ratio, their shape and the grinding media size are very importatn parameters.

All these parameters can be summarized to the mainly important parameters specific energy input, stress energy of the grinding media, number of stress events as well as the residence time distribution of the product particles in the mill.

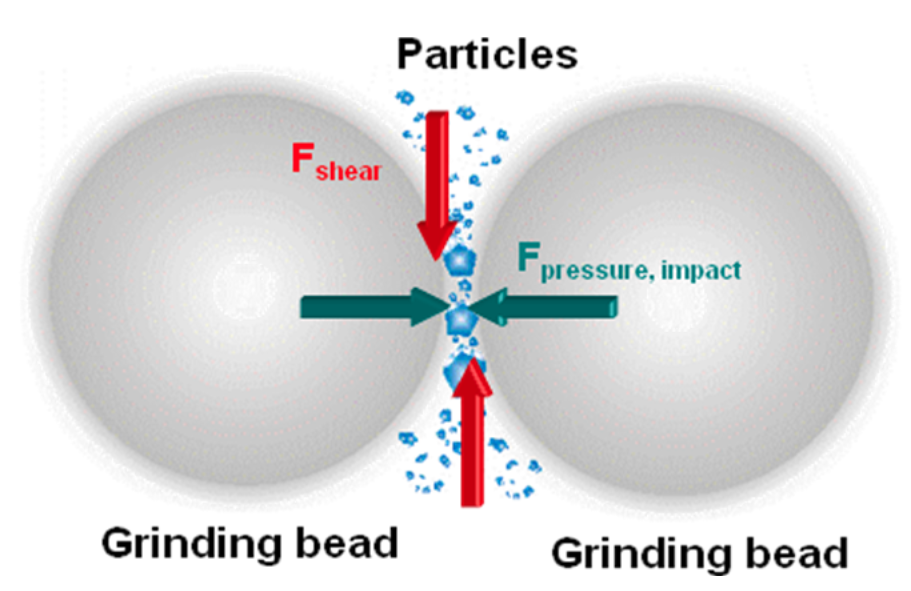

Grinding process can be divided into real comminution process and des-agglomeration processes. Whereas on the one hand for real comminution pressure and impact forces are necessary, for desagglomeration and dispersing processes shear forces are sufficient to get a grinding process.

Pressure and impact forces are always trandferred to the product particles when they are caught by the colliding grinding beads in the so called active volume. During the approach of the grinding media the fluid between the media is displaced by the beads. The displacement flow resulting thereof reaches a speed several times higher then the speed of the beads itself shortly before collision of the beads. This displacement flow leads to shear forces acting on the product particles between the approaching beads.

For more informaiton, please contact Weblande Corp.

|